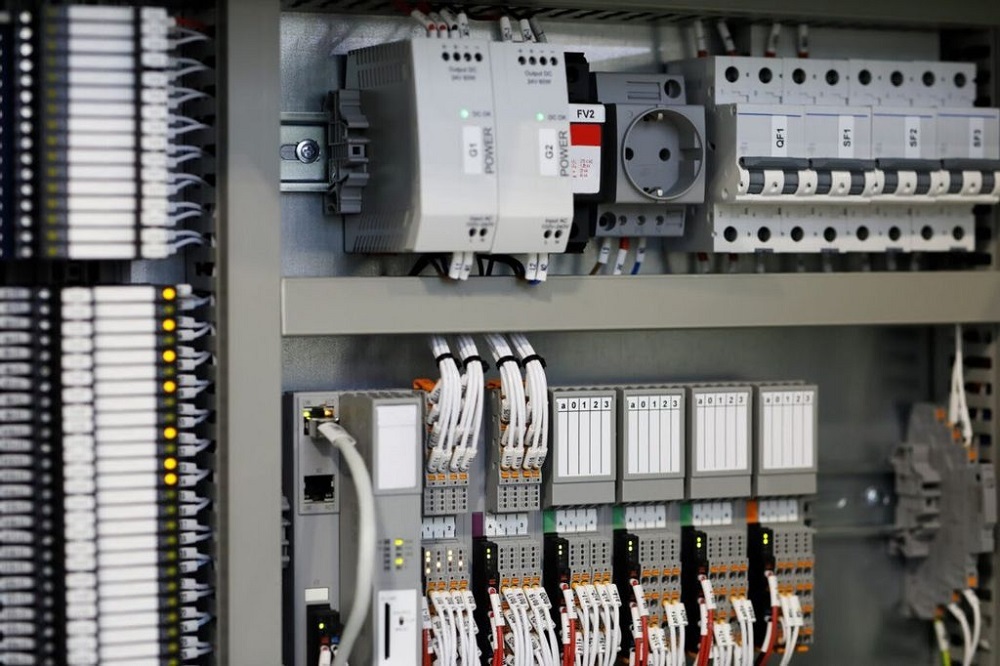

Servo System Controller is systems that consist of various components that help designers minimize the error between the operator’s command and the motor’s output. They note the discrepancy that comes in between the input and output and takes this information to an electronic controller. This controller then helps reduce this gap to a point where it ceases to exist.

How Do They Work?

The motor control unit is nothing more than a subassembly. It consists of the user interface that is the reference command along with things like the programmable controller and the amplifier. The power supply is then connected to every component that is requiring power generation while the motor is attached to the amplifier. This helps drive the load or application of the machine.

Different Types Of Servo System Controllers

The method that is used to control the servo motor’s output is based on how the controller can transmit the electronic commands with the help of signals. This is done through two methods which are the pulse-width modulation (PWM) and the Proportional, Integral, and Derivative (PID). These are the two types of controllers.

Applications And Uses

These controllers have helped by opening up an entirely new industry with several precision technologies. This has resulted in these controllers find their use in several fields like military technology, pharmaceutical manufacturing, robotics, 3D printers, and foodstuff production among others. Their capability to reduce the amount of error while also giving out the precise output allows the designers to generate an innumerable number of possibilities over the kind of things that can be implemented. One roadblock is that these systems are not only extremely complex but they also require loads of money. Apart from that, they need expert technicians who need to be skilled and dedicated enough to prevent any failures. Any chance of failure is a definite no-no because it often leads to a major catastrophe. The technicians need to ensure that the Safety systems of the Servo System Controller need to be put in place beforehand. But implementing this will further increase costs which are no doubt another headache.

Conclusion

Getting a basic understanding of these systems is essential to know how useful a Servo System Controller can be. This is a mechanism that has greatly allowed reducing errors thus making it useful in several technological fields. This development has greatly enhanced the work of several industries and it will be a useful tool in the years to come.